en Ankara Rüzgar Tüneli (ART) düşük ses altı hızlarda çalışan, kapalı devre, yatay döngülü, atmosferik ve kapalı test odasına sahip bir rüzgar tünelidir.

Cumhuriyetin muasır medeniyet seviyesi hedefinin, kendi teknolojisini üretme faaliyetlerinin ve kendi üretimini de gerçekleştirme hedefinin bir simgesi olan Ankara Rüzgar Tüneli’nin yapımına 1941 yılında karar verilen ART’nin inşaatına 1946 yılında başlanmış ve 1950 yılında inşaat tamamlanarak tünel kısmen işler hale getirilmiştir. 1956 yılında Milli Savunma Bakanlığı’na devredilen tünel herhangi bir işlerlik kazanamayıp test yapabilir hale getirilemeden 40 yıl atıl durumda kalmıştır. 1993 yılında ART’nin işletimi TÜBİTAK SAGE’ye devredilmiştir. Bakım, onarım ve yetenek artırım faaliyetleri 1996 yılında tamamlanan tünel tam kapasiteyle hizmet verebilecek seviyeye gelmiştir. 2000 yılında Subsonic Aerodynamic Testing Association (SATA) üyeliğine hak kazanmıştır. Kalkınma Bakanlığı destekli ASARTA projesi ile ART 2011 yılında bir kez daha yenilenip kapasitesi artırılmıştır.

Güvenli, hızlı ve ucuz bir şekilde tasarımların uygunluğunun değerlendirilmesi amacıyla kullanılan rüzgar tünellerinde hava ile etkileşimde olan tüm cisimlerin aerodinamik incelemeleri yapılabilmektedir. Rüzgar tüneli denemeleri sayısal çözümlemelerin doğrulanması, uçuş denemelerinin/işlevsel testlerin maliyet etkin ve güvenli yapılabilmesi için mutlaka uygulanması gereken önemli süreçlerden biridir.

Rüzgar tünellerinde uçak, helikopter, İHA, paraşüt gibi hava taşıtları ile otomobil, kamyon, otobüs ve motosiklet gibi kara taşıtlarının aerodinamik özelliklerinin incelenmesi, siren ve paratoner gibi cisimlerin hava ile etkileşimlerinin belirlenmesi ve fırtına ortamında dayanımlarının incelenmesi gibi pek çok deney gerçekleştirilebilmektedir.

Ankara Rüzgar Tüneli (ART) düşük ses altı hızlarda çalışan, kapalı devre, yatay döngülü, atmosferik ve kapalı test odasına sahip bir rüzgar tünelidir. Test odası genişliği 3.05 m, yüksekliği 2.44 m ve uzunluğu 6.10 metredir. Tünel döngüsü betonarme olup test odası ahşaptır. Test odasında modelin olmadığı durumda 80 m/s (288 km/saat) hıza ulaşılabilmektedir. Tünelin sahip olduğu eksenel türbülans seviyesi %0.15, toplam türbülans seviyesi %0.62’dir.

ART-Ankara Rüzgar Tüneli, 1:40 ölçekli modeli, 1946 İzmir Enternasyonal Fuarı, THK Broşürü

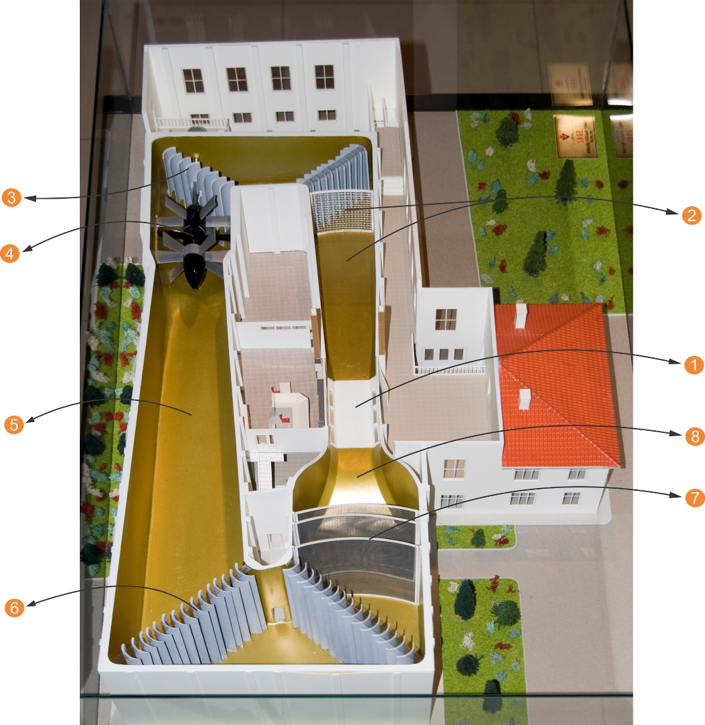

Aşağıdaki şekilde Ankara Rüzgar Tüneli’nin bölmeleri ve teknik özellikleri verilmektedir.

ART Bölümleri ve Özellikleri

| * | Bölüm Adı | Özellikler |

|---|---|---|

| 1 | Test Odası | Boyutlar: 3.05m * 2.44m * 6.1m |

| 2 | Genişleme Konisi Ve Metal Elek | Genişleme açısı: 5° (yatay), 6.3° (dikey), Uzunluk: 15m |

| 3 | Birinci İki Sıra Dönme Kanatçıkları | İlk iki köşede hücum kenarı beton, firar kenarı ahşap. |

| 4 | Pervane Ve Doğrultucu Kanatçıklar | 5.18 m çaplı 4 kanatlı pervane, 220mm çaplı mil üzerinde 1000 BG (750 kW) gücündeki doğru akım motoru ile en yüksek 600 devir/dakika; 7 adet doğrultucu kanatçık. |

| 5 | İkinci Genişleme Konisi | Genişleme açısı: 6.4° (Her iki yönde), Uzunluk: 24.5m |

| 6 | İkinci İki Sıra Dönme Kanatçıkları | İki sırada eşlenik 22 dönme kanatçığı, hücum kenarı beton, firar kenarı ahşap malzeme. |

| 7 | Akım Düzenleyici Perdeler | Daralma konisinden önce 1 m aralıklarla 3 adet, tek parça metal. |

| 8 | Dinlenme Odası Ve Daralma Konisi | Daralma oranı: 7.5 |

| 9 | Toplam Oturma Alanı | 47.5m X 17.5m |

ART’de deneyi yapılacak cismin kendisi veya ölçekli modeli deneyin yapıldığı test odasına monte edilmekte, istenen hızda rüzgar verilmekte, model istenen açıya getirilerek dış balans veya iç balans sistemleri yardımıyla modele etkiyen aerodinamik kuvvetler ölçülmekte ve akımın incelenmesi için çeşitli tekniklerle akım görüntüleme testleri gerçekleştirilebilmektedir. Günümüze kadar ART Savunma Sanayii şirketleri olan TÜBİTAK SAGE, ASELSAN, ROKETSAN ve TUSAŞ başta olmak üzere üniversiteler ve sivil sektör firmaları tarafından aktif olarak kullanılmıştır. Ayrıca 2000 yılında ART düşük hızlı rüzgar tünellerinin tasarımı, işletimi, bakımı ve fiziksel ölçüm ile enstrümantasyonu gibi konular hakkındaki sorunların görüşülmesi ve fikir alışverişinde bulunulması amacıyla kurulmuş dünya çapında bir organizasyon olan Subsonic Aerodynamic Testing Association (SATA) üyeliğine hak kazanmıştır. ART’de havacılık başta olmak üzere otomotiv ve sivil uygulamalar gibi farklı kategorilerde çok sayıda test gerçekleştirilmiştir.